Stainless Steel Casting

Our stainless steel casting services are designed to meet the demands of diverse industries, providing exceptional durability, corrosion resistance, and precision. Utilizing advanced techniques such as lost foam casting, sand casting, gravity casting, and resin sand casting, we deliver components that excel in performance and reliability.

- Competitive Price 30% cost save

- Fast turnaround in 7 days

- Tolerances down to ±0.005mm

- Global Delivery

- Real Factory

Request A Quote Today!

"*" indicates required fields

Manufacturing experience

Happy Customers

Custom Machined

Exporting Countries

What are the Advantages of Stainless Steel Investment Castings?

Stainless steel's biggest advantage is its excellent corrosion resistance. Unlike other materials, stainless steel castings have a built-in chromium oxide layer that provides exceptional anti-corrosive properties. These corrosion-resistant properties make stainless steel castings ideal for pump/valve, petrochemical, marine, and other industrial applications.

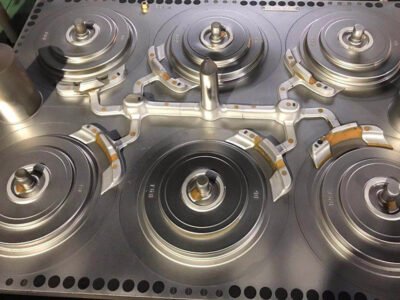

Lost Foam Casting

Lost foam casting is an innovative process that uses expendable foam patterns to produce intricate stainless steel components. This technique allows for highly detailed and complex shapes, reducing the need for additional machining.

Lost foam casting is widely used in automotive, aerospace, and machinery industries, offering lightweight yet robust solutions for high-performance applications.

Advantages:

- Excellent surface finish and dimensional accuracy.

- Ideal for complex geometries and thin-walled designs.

- Reduces waste and improves production efficiency.

Sand Casting

Features:

- Applicable for both small and large production runs.

- Works with a wide range of stainless steel grades.

- Offers flexibility in part sizes and designs.

Sand casting is commonly used in industries such as construction, transportation, and industrial equipment manufacturing, where durability and strength are essential.

Gravity Casting

Gravity casting involves pouring molten stainless steel into a mold using gravity as the driving force. This method is ideal for producing parts with superior mechanical properties and consistent quality.

Gravity casting is frequently employed in the production of components for medical devices, food processing equipment, and precision instruments due to its ability to deliver high-quality, reliable parts.

Benefits:

- Produces dense and high-strength components.

- Suitable for medium to high production volumes.

- Delivers excellent dimensional stability and surface quality.

Resin Sand Casting

Resin sand casting utilizes resin-coated sand to create durable molds for stainless steel casting. This method offers high precision and excellent surface finishes, making it ideal for intricate designs.

Advantages

- Enhanced dimensional accuracy and surface smoothness.

- Strong molds for complex and detailed designs.

- Suitable for high-strength and wear-resistant parts.

Resin sand casting is widely used in industries like petrochemicals, energy, and heavy machinery, where components must withstand harsh operating conditions.

Why Choose Our Stainless Steel Casting Services?

Expertise

Years of experience in stainless steel casting ensure superior quality and precision.

Advanced Technology

Proficiency in multiple casting methods to meet diverse application needs.

Material Excellence

Use of high-grade stainless steel for exceptional durability and corrosion resistance.

Customization

Tailored solutions to match your unique design and functional requirements.

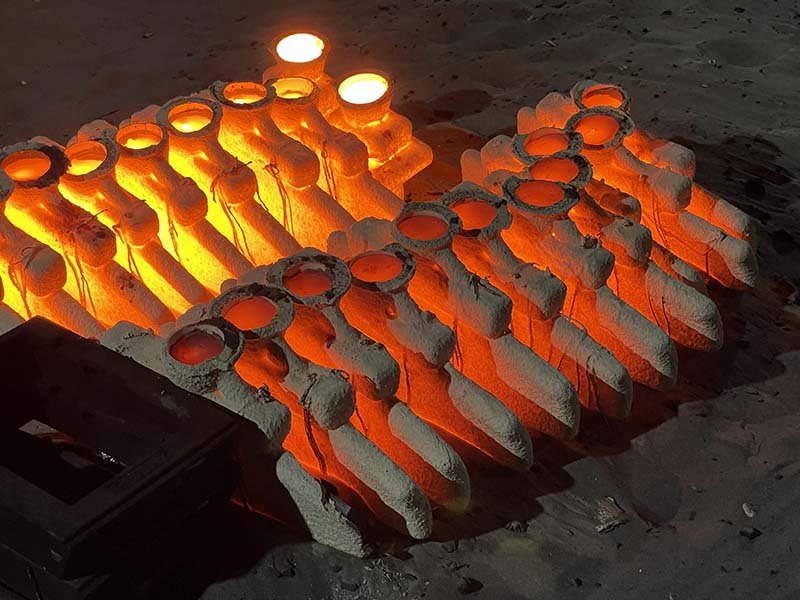

The Casting Process

The process of casting involves several key steps that ensure the quality and precision of the final component:

Pattern Creation

Mold Making

Melting and Pouring

Cooling and Solidification