Difference between castings and forgings

1: Processing technology castings It is made by casting process; First heat metal materials (such as cast iron, cast steel, aluminum alloy, etc.) into a liquid state, and then pour them into the prefabricated mold cavity of a specific shape, After the liquid metal is cooled and solidified, a casting with a shape similar to the cavity is obtained; Common castings include sand casting, investment casting, die casting, etc. Forgings are produced by forging technology; + Eat roast First heat the solid metal billet (such as bar, ingot, etc.) to a certain solid state temperature to improve the plasticity, and then use forging equipment to press to make it plastic deform, so that the required shape and size of the forging; Common forgings include free forging, die forging, etc.

II: Internal Organization castings Because it is formed by solidification of liquid metal, there will be dendritic structure inside when solidification, It is also prone to defects such as shrinkage holes, pores, and inclusions, which will affect its mechanical properties, especially for strength and toughness. However, the internal organization can be improved to a certain extent through subsequent processes such as heat treatment. Forgings eaten and cooked + During the forging process, the metal billet is plastic deformed repeatedly Grains are broken and refined, and defects such as pores and shrinkage holes are compacted and welded under pressure. This makes the internal structure of the forgings denser and more uniform, and the mechanical properties (especially strength and toughness) are significantly improved compared with the castings. Withstands higher working loads.

Three: Mechanical properties castings Generally speaking, the mechanical properties of castings are low, Due to internal defects and relatively grain structure, its strength, toughness, and fatigue life are not as good as forgings; However, the properties of castings with different materials and processes are different, and high-performance cast alloys combined with advanced processes can perform well. Forgings + With high mechanical properties, its strength, toughness, hardness and other indicators are often better than castings, Because its internal tissue is dense and uniform. It has good reliability under complex load conditions such as alternating and impact, and is often used to manufacture key components that require high mechanical properties, such as engine blades and automobile crankshafts.

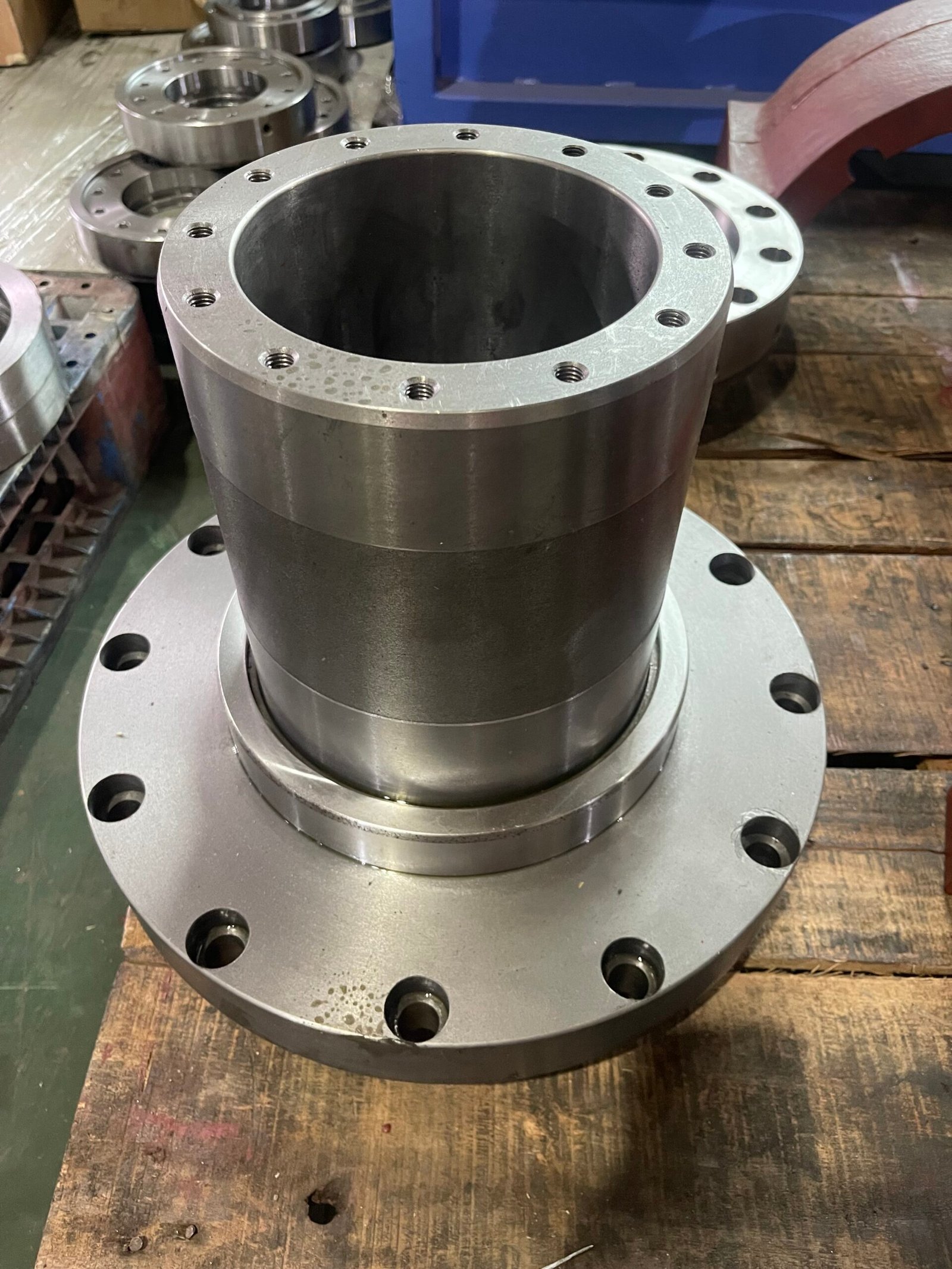

Four: Appearance and dimensional accuracy castings The appearance surface is relatively rough, and the surface roughness of the mold cavity and the process of demoulding may cause surface damage. Its dimensional accuracy is also low, and it is generally difficult to achieve high dimensional accuracy control in the casting process. Follow-up machining is often required to achieve the design accuracy. Forgings + The external surface is opposite, and the metal surface is flat and smooth after being pressed by the forging equipment, High dimensional precision, the use of advanced forging technology such as die forging can accurately control the size, and can follow-up machining.

Five: Application fields castings Widely used in construction, machinery manufacturing, automobiles, and other fields, It mainly manufactures parts with complex shapes, not particularly high requirements for mechanical properties and large batches. Like car engine cylinder block, building cast iron pipe fittings, etc. Forgings + It is often used in occasions where mechanical properties and reliability are extremely high. Key parts (landing gear, rocket engine shell, etc.), ship spindle, key transmission parts of construction machinery, etc.

GUANGDONG BRIDGE TECHNOLOGY CO LTD

WhatsApp: 0086 134 2210 8513

mailbox: 821460933@qq.com

http://www.bridge.wiki

www.bridge.icu