china stainless steel investment casting producer

As a professional China stainless steel investment casting producer, we have extensive experience in providing high-quality investment castings for various industries. In this article, we will delve into the intricacies of stainless steel investment casting, its applications, and the advantages it offers over other casting methods. By the end of this article, you will have a comprehensive understanding of this specialized process and its significance in the industry.

I. Basics of Stainless Steel Investment Casting

1.1 Definition and Principle

Stainless steel investment casting is a precision casting technique that utilizes a ceramic shell mold to produce complex-shaped parts with high accuracy and surface finish. The process involves creating a pattern, which is then used to produce a wax prototype. The wax prototype is then coated with ceramic slurry, sintered, and melted out to leave a hollow ceramic shell. Molten stainless steel is then poured into the shell, allowing it to solidify and take the shape of the original pattern.

1.2 Materials

Stainless steel investment casting is primarily used for stainless steel alloys, which are known for their excellent corrosion resistance, high strength, and heat resistance. The most commonly used stainless steel grades in investment casting include 304, 316, 321, and 347.

1.3 Equipment

The equipment required for stainless steel investment casting includes:

– Pattern making machine

– Wax injection machine

– Ceramic shell mold production line

– Casting furnace

– Cooling and handling equipment

II. Applications of Stainless Steel Investment Casting

2.1 Automotive Industry

Stainless steel investment casting is widely used in the automotive industry for manufacturing engine components, exhaust systems, and intake manifolds. Its high strength and corrosion resistance make it an ideal material for these applications.

2.2 Aerospace Industry

The aerospace industry relies on stainless steel investment casting for producing critical components such as turbine blades, combustion chambers, and fuel nozzles. These components require high-temperature resistance and excellent structural integrity.

2.3 Medical Industry

Stainless steel investment casting is used in the medical industry for producing surgical instruments, orthopedic implants, and dental devices. The material’s biocompatibility and corrosion resistance make it suitable for these applications.

2.4 Machinery and Equipment Industry

This industry utilizes stainless steel investment casting for manufacturing valves, pumps, and other mechanical components that require high precision and durability.

III. Advantages of Stainless Steel Investment Casting

3.1 High Precision and Complex Shape

Stainless steel investment casting allows for the production of complex-shaped parts with high accuracy and surface finish. This is due to the precision of the ceramic shell mold and the wax pattern.

3.2 Excellent Material Properties

Stainless steel investment casting retains the excellent material properties of stainless steel, such as corrosion resistance, high strength, and heat resistance.

3.3 Cost-Effective

Compared to other casting methods, stainless steel investment casting is more cost-effective for producing complex-shaped parts with high precision and surface finish.

3.4 Environmentally Friendly

The process of stainless steel investment casting is environmentally friendly, as it minimizes waste and requires less energy compared to other casting methods.

IV. Production Process of Stainless Steel Investment Casting

4.1 Pattern Making

The pattern making process involves creating a master pattern, which is then used to produce wax prototypes. The master pattern can be made of wood, plastic, or metal.

4.2 Wax Injection

The wax injection process involves injecting molten wax into the master pattern to produce wax prototypes. These prototypes are then used to create the ceramic shell mold.

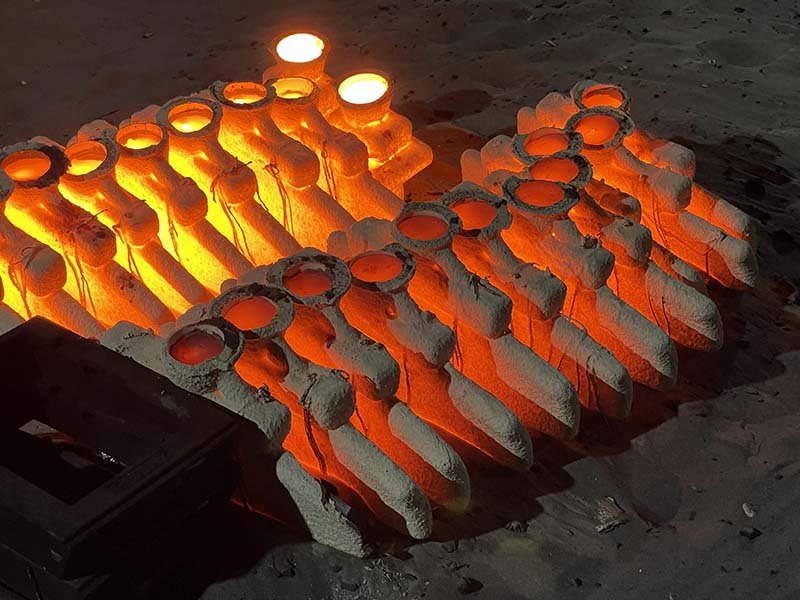

4.3 Ceramic Shell Mold Production

The ceramic shell mold is produced by applying a ceramic slurry to the wax prototype, followed by drying and sintering. The wax is then melted out, leaving a hollow ceramic shell.

4.4 Casting

Molten stainless steel is poured into the ceramic shell mold, allowing it to solidify and take the shape of the original pattern. The casting is then cooled and removed from the mold.

4.5 Finishing

The casting is then cleaned, heat-treated, and polished to achieve the desired surface finish.

V. Common Issues and Solutions in Stainless Steel Investment Casting

5.1 Issue: Poor surface finish

Solution: Ensure proper preparation of the ceramic shell mold, control the pouring temperature, and optimize the cooling process.

5.2 Issue: Incomplete filling

Solution: Optimize the pouring speed and temperature, and ensure the ceramic shell mold is properly designed.

5.3 Issue: Gas porosity

Solution: Improve the ceramic shell mold quality, optimize the pouring temperature, and reduce the casting speed.

5.4 Issue: Cracking

Solution: Use high-quality stainless steel material, optimize the casting temperature, and ensure proper heat treatment.

5.5 Issue: Shrinkage

Solution: Control the pouring temperature and cooling rate, and optimize the mold design.

as a professional China stainless steel investment casting producer, we have the expertise and experience to provide high-quality investment castings for various industries. By understanding the basics, applications, advantages, production process, and common issues of stainless steel investment casting, you can make informed decisions when selecting a reliable supplier for your projects.