Sand Casting: The Time-Tested Workhorse of Metal Manufacturing

Sand casting, one of the oldest and most versatile metalworking processes, has been instrumental in shaping human civilization for millennia. From ancient bronze sculptures to modern automotive engine blocks, this method involves pouring molten metal into a sand mold to create complex, durable parts. Despite the rise of advanced technologies like 3D printing and die casting, sand casting remains irreplaceable due to its cost-effectiveness, scalability, and adaptability to a wide range of metals and geometries.

This article explores the fundamentals of sand casting, its advantages and limitations, key applications, environmental considerations, y future innovations driving its evolution.

1. The Sand Casting Process: A Step-by-Step Breakdown

Sand casting involves several critical stages:

1.1 Pattern Making

- Purpose: A pattern (typically wood, plastic, or metal) replicates the final part’s shape, including allowances for shrinkage and machining.

- Types:

- Single-piece patterns: For simple, flat parts.

- Split patterns: Divided into two halves for complex geometries.

- Match plate patterns: Mounted on a plate for efficient handling.

1.2 Mold Assembly

- Molding Sand: A mixture of silica sand, binders (clay, resin, or chemicals), and water.

- Core Making: Sand cores (if needed) create internal cavities (e.g., engine cylinder holes).

- Mold Construction:

- Green Sand Molding: Uses moist sand (most common for low-volume runs).

- No-Bake Molding: Uses chemically bonded sand for higher precision.

- Shell Molding: Coats a heated pattern with resin-coated sand for thin-walled parts.

1.3 Pouring & Solidification

- Melting: Metal is heated in a furnace (e.g., induction, electric arc, or cupola).

- Pouring: Molten metal is poured into the mold cavity via a sprue and runner system.

- Solidification: The metal cools and shrinks, requiring risers to feed additional metal and prevent voids.

1.4 Shakeout & Finishing

- Mold Breakdown: The sand mold is shattered to retrieve the casting.

- Cleaning: Excess sand, gates, and risers are removed via grinding, shot blasting, or cutting.

- Tratamiento térmico: Some castings undergo annealing, quenching, or tempering to improve mechanical properties.

2. Advantages of Sand Casting

2.1 Cost-Effectiveness for Low to Medium Production Volumes

- Low Tooling Costs: Patterns are cheaper than dies for die casting.

- No Size Limitations: Can produce parts weighing from grams to tons (e.g., ship propellers).

2.2 Material Versatility

- Ferrous Alloys: Cast iron, steel, and stainless steel.

- Non-Ferrous Alloys: Aluminum, copper, bronze, and magnesium.

- Exotic Alloys: Nickel-based superalloys for aerospace.

2.3 Design Flexibility

- Complex Geometries: Undercuts, internal passages, and thin walls are achievable with cores.

- Rapid Prototyping: Wood or 3D-printed patterns enable quick iterations.

2.4 Sustainability Benefits

- Reusable Sand: Up to 95% of sand can be recycled via mechanical reclamation.

- Lower Energy Use: Compared to forging or machining, sand casting consumes less energy per part.

3. Limitations of Sand Casting

Despite its strengths, sand casting has drawbacks:

- Dimensional Accuracy: Surface finish (Ra 12.5–50 μm) and tolerances (CT10–13) are inferior to die casting or investment casting.

- Post-Processing Required: Heavy machining is often needed to achieve tight tolerances.

- Environmental Concerns: Dust emissions and waste sand disposal if not properly recycled.

- Slower Cycle Times: Not ideal for high-volume production (e.g., millions of parts per year).

4. Key Applications of Sand Casting

4.1 Automotive Industry

- Engine Blocks & Cylinder Heads: Due to their large size and complex cooling passages.

- Transmission Cases & Brake Components: Cost-effective for low-volume variants.

4.2 Construction & Heavy Machinery

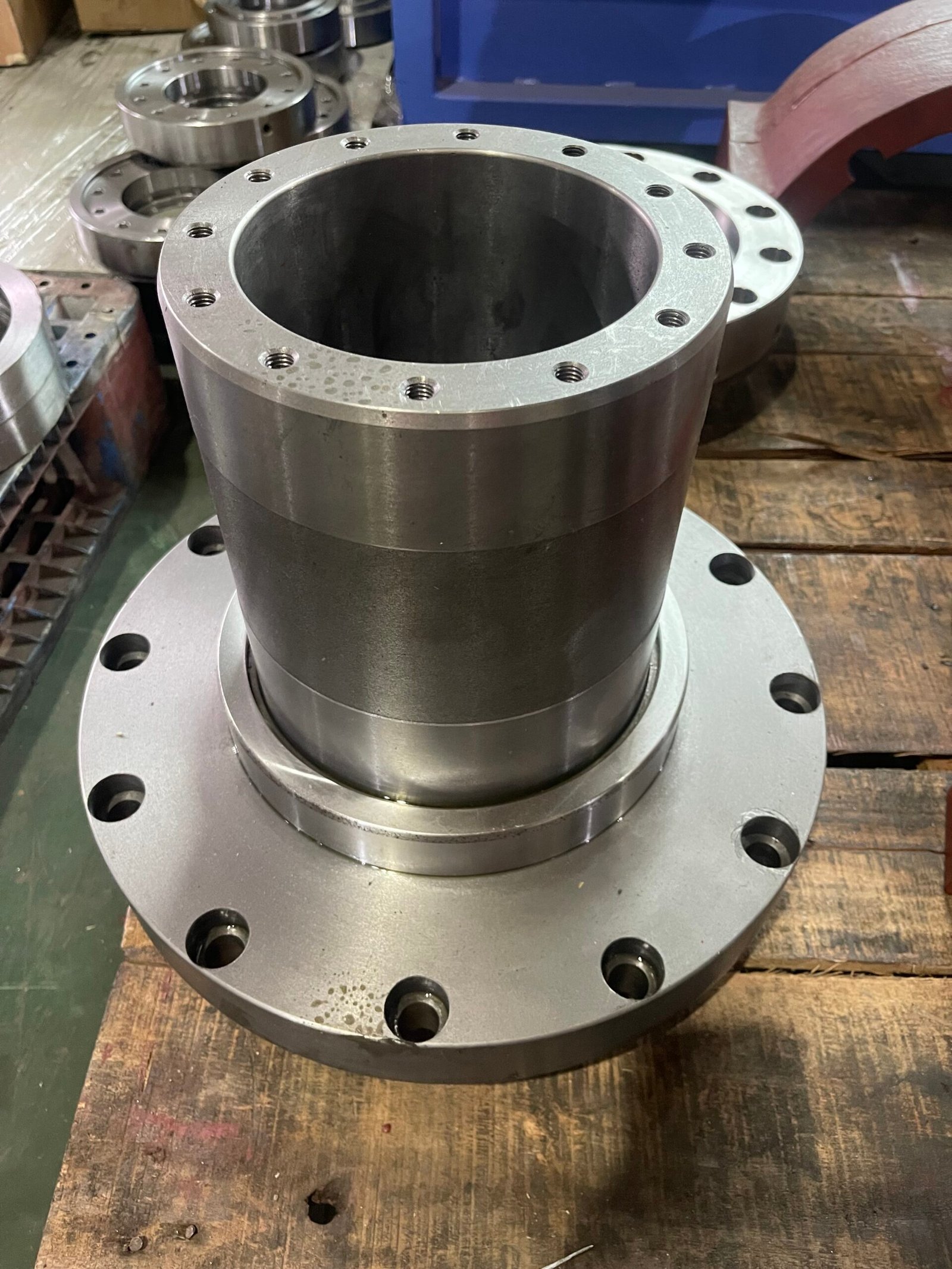

- Pump Housings & Valve Bodies: Corrosion-resistant cast iron parts.

- Agricultural Equipment: Gearboxes and structural components.

4.3 Art & Sculpture

- Bronze Statues & Monuments: Sand casting enables intricate detailing in large-scale artworks.

4.4 Aerospace & Defense

- Landing Gear Components: High-strength steel castings for durability.

- Rocket Engine Parts: Nickel alloys for extreme temperatures.

4.5 Energy Sector

- Wind Turbine Housings: Large, lightweight aluminum castings.

- Oil & Gas Valves: Corrosion-resistant stainless steel parts.

5. Innovations in Sand Casting

5.1 Advanced Molding Materials

- Ceramic Shell Molds: For thin-walled, high-precision parts.

- 3D-Printed Sand Molds: Eliminates pattern-making, enabling rapid prototyping.

5.2 Simulation & Process Optimization

- Casting Simulation Software: Predicts defects (e.g., shrinkage, porosity) before production.

- Real-Time Monitoring: Sensors track temperature, pressure, and fluidity during pouring.

5.3 Sustainable Practices

- Chemically Bonded Sands: Reduces dust emissions compared to green sand.

- Closed-Loop Sand Recycling: Minimizes waste and lowers material costs.

5.4 Hybrid Casting Processes

- Sand Casting + CNC Machining: Combines low-cost prototyping with precision finishing.

- Sand Casting + Additive Manufacturing: 3D-printed cores for complex internal geometries.

6. Environmental & Safety Considerations

- Dust Control: Ventilation systems and wet scrubbers reduce silica dust exposure.

- Gestión de residuos: Recycling spent sand into concrete or road base.

- Energy Efficiency: Electric furnaces and renewable energy integration reduce carbon footprints.

Conclusion

Sand casting remains a cornerstone of metal manufacturing, offering unmatched flexibility, affordability, and scalability. While newer technologies like die casting and 3D printing excel in high-precision, high-volume applications, sand casting continues to thrive in industries where cost, size, and material diversity are paramount.

By embracing innovations in materials, simulation, and sustainability, sand casting is poised to remain relevant in the Industry 4.0 era, ensuring its role in shaping the future of manufacturing.

Frequently Asked Questions (FAQs) about Sand Casting

Q1: What metals are commonly cast using sand casting?

A: Sand casting supports a wide range, including cast iron, steel, aluminum, bronze, copper, and magnesium, as well as high-performance alloys like nickel-based superalloys.

Q2: How does sand casting compare to die casting in terms of cost?

A: Sand casting is cheaper for low-volume production (tooling costs are lower), while die casting is more economical for high volumes (faster cycle times and lower per-unit costs).

Q3: Can sand casting produce parts with tight tolerances?

A: Sand casting typically achieves CT10–13 tolerances, which is less precise than die casting (CT5–8) but sufficient for many industrial applications.

Q4: What is the maximum size of a sand-cast part?

A: Sand casting can produce parts weighing up to 100 tons, making it ideal for large components like ship propellers, wind turbine bases, and machine frames.

Q5: Is sand casting environmentally friendly?

A: Yes, when practiced sustainably. Up to 95% of sand can be recycled, and energy use is lower than forging or machining. However, dust emissions and waste management must be controlled.

Q6: How long does the sand casting process take?

A: Cycle times vary but typically range from a few hours (for small parts) to days (for large, complex castings). Die casting is faster but limited to smaller parts.

Q7: Can sand casting be automated?

A: Yes, modern foundries use robotic pouring, automated mold handling, and CNC finishing to improve efficiency and consistency.