Casting Alloys

Our casting alloy services provide precision manufacturing for a variety of applications, ensuring durability, accuracy, and performance in every project. With expertise in a wide range of metals and advanced casting techniques, we deliver superior products tailored to meet your specific requirements. From prototyping to production, we guarantee quality at every step.

- Competitive Price 30% cost save

- Fast turnaround in 7 days

- Tolerances down to ±0.005mm

- Global Delivery

- Real Factory

Request A Quote Today!

"*" indicates required fields

Manufacturing experience

Happy Customers

Custom Machined

Exporting Countries

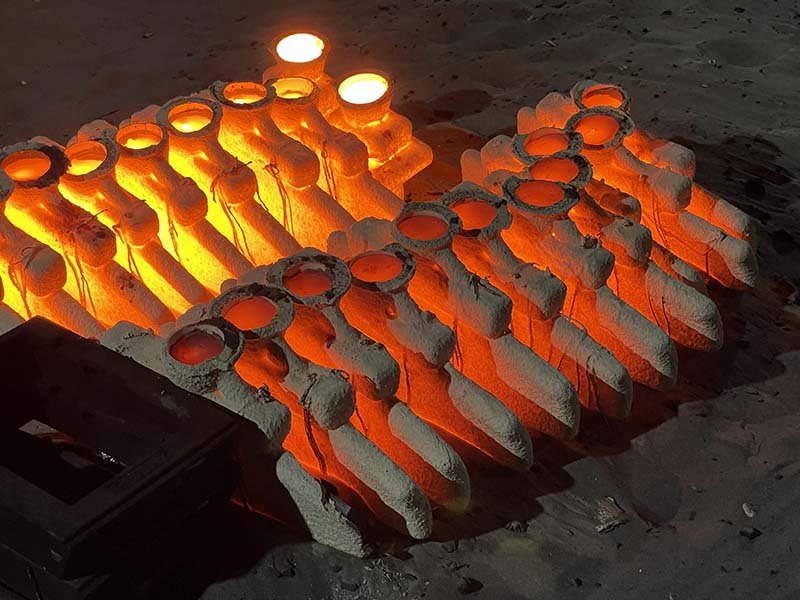

What Is Investment Casting ?

Investment casting is a complex process where a molten alloy is poured into a ceramic shell to create small, precise metal components. Its original name "lost wax casting," refers to the original wax pattern the ceramics are formed around, then melted and replaced with alloys of stainless steel, aluminum, cobalt, carbon steel, brass, bronze, and other metals.Professional Factory's Rapid Prototyping Die Castand Stainless Steel Investment Die Casting Precision Customized Metal.

Investment Casting

Investment casting, also known as lost-wax casting, is a versatile process that delivers intricate and precise components. We use high-quality casting alloys to produce parts with excellent surface finishes and minimal post-processing. This method is ideal for creating complex geometries, including thin walls and undercuts, making it widely applicable across aerospace, automotive, and medical industries.

Our investment casting capabilities include:

- A variety of alloys, including stainless steel, carbon steel, aluminum, and brass.

- Tight tolerances for precision-critical components.

- Custom designs tailored to meet specific industry requirements.

Secondary Services

To complement our casting services, we offer a range of secondary processes to enhance the functionality and appearance of your components. Our secondary services include

Machining

High-precision CNC machining for tighter tolerances and refined finishes.

Heat Treatment

Strengthening and hardening alloys for improved mechanical properties.

Surface Finishing

Polishing, plating, and coating options for corrosion resistance and aesthetics.

Assembly

Integration of multiple components into a finished product for seamless solutions.

These services ensure that your casting alloy products are production-ready and meet the highest quality standards.

Rapid Prototype Casting

Our rapid prototype casting service accelerates the development cycle, allowing you to test and refine designs before full-scale production. Using advanced technologies, such as 3D printing and quick mold development, we create accurate prototypes in a fraction of the time required by traditional methods.

Whether you need a single prototype or a small batch, we ensure high-quality results that match your final production standards.

Key benefits of our rapid prototype casting include:

- Faster time to market for new products.

- Cost-effective testing of designs and materials.

- Enhanced design flexibility for iterative improvements.

Metal Casting

Cast Iron

Bronze

Cast Iron

Copper

Stainless Steel

Steel

Titanium

Tool Steel

Aluminum

Cast Iron

Our metal casting services feature:

- A broad range of materials, including iron, aluminum, copper, and exotic alloys.

- Custom mold designs for unique and complex geometries.

- Scalability to accommodate both small and large production runs.

With stringent quality control measures, we ensure that every casting meets your specifications and exceeds your expectations.

Specialty Metals

Examples of specialty metals we work with include:

- Titanium Alloys: Lightweight, strong, and resistant to extreme environments.

- Nickel Alloys: Ideal for high-temperature and high-corrosion applications.

- Cobalt Alloys: Known for exceptional wear resistance and mechanical strength.

Our expertise in specialty metals allows us to deliver solutions for industries such as aerospace, energy, and medical devices, where superior material performance is critical.

Why Choose Our Casting Alloy Services?

Expertise

Decades of experience in casting and secondary processes ensure high-quality results.

Advanced Technology

State-of-the-art equipment for precision and efficiency.

Material Variety

Extensive options for casting alloys to meet diverse application needs.

Customization

Tailored solutions to match your specifications and performance requirements.

The Casting Process

The process of casting involves several key steps that ensure the quality and precision of the final component:

Pattern Creation

Mold Making

Melting and Pouring

Cooling and Solidification

Finishing and Machining

Casting Alloys

Our casting alloy services provide precision manufacturing for a variety of applications, ensuring durability, accuracy, and performance in every project. With expertise in a wide range of metals and advanced casting techniques, we deliver superior products tailored to meet your specific requirements. From prototyping to production, we guarantee quality at every step.

- Competitive Price 30% cost save

- Fast turnaround in 7 days

- Tolerances down to ±0.005mm

- Global Delivery

- Real Factory

Request A Quote Today!

"*" indicates required fields

Manufacturing experience

Happy Customers

Custom Machined

Exporting Countries

What Is Investment Casting ?

Investment casting is a complex process where a molten alloy is poured into a ceramic shell to create small, precise metal components. Its original name "lost wax casting," refers to the original wax pattern the ceramics are formed around, then melted and replaced with alloys of stainless steel, aluminum, cobalt, carbon steel, brass, bronze, and other metals.Professional Factory's Rapid Prototyping Die Castand Stainless Steel Investment Die Casting Precision Customized Metal.

Investment Casting

Investment casting, also known as lost-wax casting, is a versatile process that delivers intricate and precise components. We use high-quality casting alloys to produce parts with excellent surface finishes and minimal post-processing. This method is ideal for creating complex geometries, including thin walls and undercuts, making it widely applicable across aerospace, automotive, and medical industries.

Our investment casting capabilities include:

- A variety of alloys, including stainless steel, carbon steel, aluminum, and brass.

- Tight tolerances for precision-critical components.

- Custom designs tailored to meet specific industry requirements.

Secondary Services

To complement our casting services, we offer a range of secondary processes to enhance the functionality and appearance of your components. Our secondary services include

Machining

High-precision CNC machining for tighter tolerances and refined finishes.

Heat Treatment

Strengthening and hardening alloys for improved mechanical properties.

Surface Finishing

Polishing, plating, and coating options for corrosion resistance and aesthetics.

Assembly

Integration of multiple components into a finished product for seamless solutions.

These services ensure that your casting alloy products are production-ready and meet the highest quality standards.

Rapid Prototype Casting

Our rapid prototype casting service accelerates the development cycle, allowing you to test and refine designs before full-scale production. Using advanced technologies, such as 3D printing and quick mold development, we create accurate prototypes in a fraction of the time required by traditional methods.

Whether you need a single prototype or a small batch, we ensure high-quality results that match your final production standards.

Key benefits of our rapid prototype casting include:

- Faster time to market for new products.

- Cost-effective testing of designs and materials.

- Enhanced design flexibility for iterative improvements.

Metal Casting

Cast Iron

Bronze

Cast Iron

Copper

Stainless Steel

Steel

Titanium

Tool Steel

Aluminum

Cast Iron

Our metal casting services feature:

- A broad range of materials, including iron, aluminum, copper, and exotic alloys.

- Custom mold designs for unique and complex geometries.

- Scalability to accommodate both small and large production runs.

With stringent quality control measures, we ensure that every casting meets your specifications and exceeds your expectations.

Specialty Metals

Examples of specialty metals we work with include:

- Titanium Alloys: Lightweight, strong, and resistant to extreme environments.

- Nickel Alloys: Ideal for high-temperature and high-corrosion applications.

- Cobalt Alloys: Known for exceptional wear resistance and mechanical strength.

Our expertise in specialty metals allows us to deliver solutions for industries such as aerospace, energy, and medical devices, where superior material performance is critical.

Why Choose Our Casting Alloy Services?

Expertise

Decades of experience in casting and secondary processes ensure high-quality results.

Advanced Technology

State-of-the-art equipment for precision and efficiency.

Material Variety

Extensive options for casting alloys to meet diverse application needs.

Customization

Tailored solutions to match your specifications and performance requirements.

The Casting Process

The process of casting involves several key steps that ensure the quality and precision of the final component:

Pattern Creation

Mold Making

Melting and Pouring

Cooling and Solidification