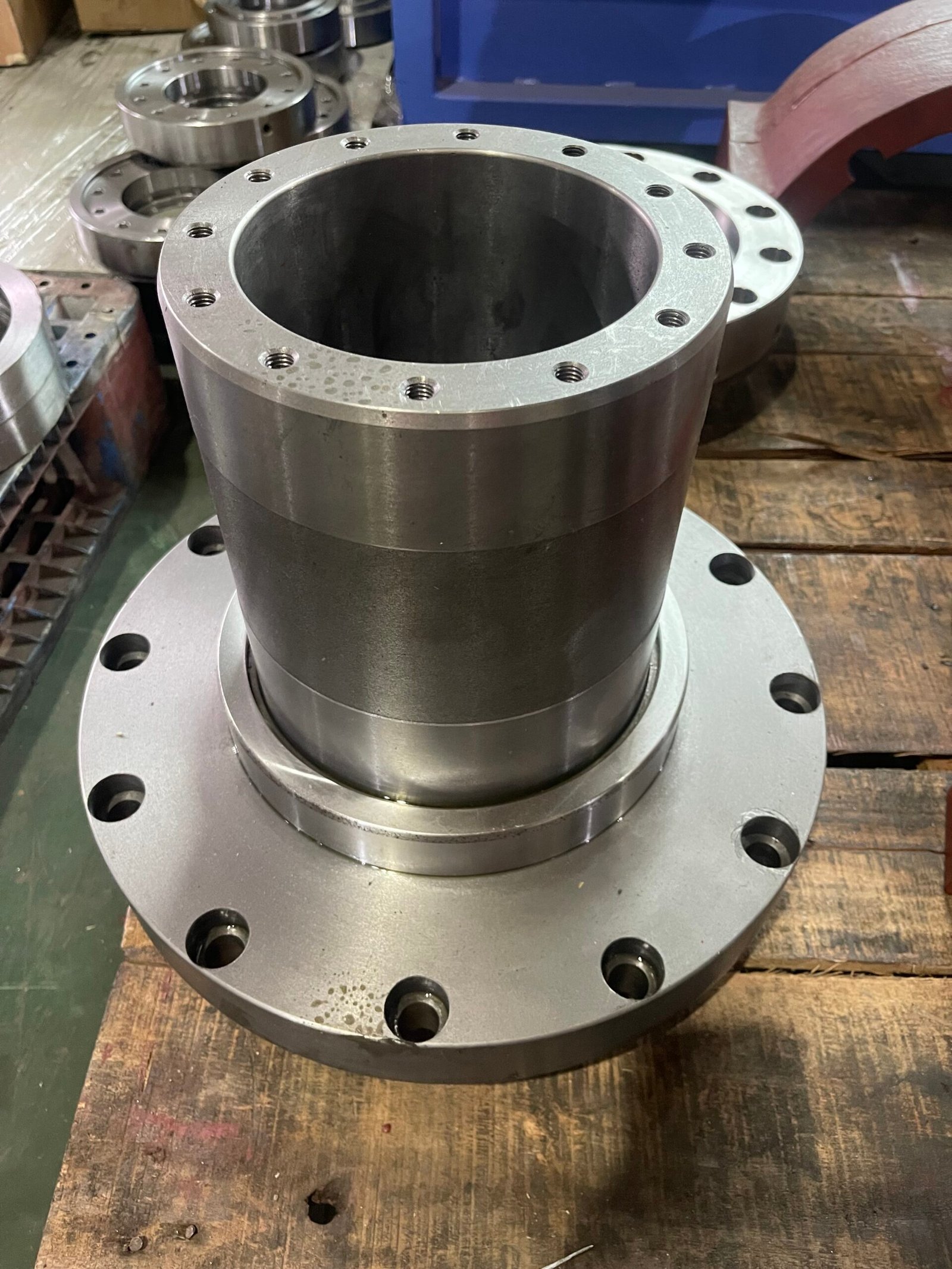

300 series investment cast stainless steel

300 series investment cast stainless steel is a popular choice for various applications due to its excellent corrosion resistance, high strength, and aesthetically pleasing appearance. In this article, we will delve into the properties, applications, advantages, and challenges of using 300 series investment cast stainless steel.

Properties of 300 Series Investment Cast Stainless Steel

300 series investment cast stainless steel belongs to the austenitic stainless steel family, which is characterized by its face-centered cubic crystal structure. The main elements in this series include iron, chromium, nickel, and manganese. The following are the key properties of 300 series investment cast stainless steel:

1. Corrosion Resistance: The high content of chromium in 300 series stainless steel forms a passive film on the surface, which prevents the steel from being corroded by the environment. This makes it suitable for use in harsh environments such as marine, chemical, and food industries.

2. High Strength: 300 series investment cast stainless steel has excellent strength and toughness, which can be further improved through cold working. This allows it to withstand heavy loads and mechanical stress.

3. Aesthetically Pleasing Appearance: The bright, lustrous surface of 300 series stainless steel makes it suitable for decorative applications, such as architectural facades and kitchen utensils.

4. Ease of Fabrication: 300 series investment cast stainless steel can be easily,Welding, cutting, bending, and forming to meet various processing needs.

5. Weldability: The excellent weldability of 300 series stainless steel allows for easy joining of components, reducing the need for post-weld heat treatment.

Applications of 300 Series Investment Cast Stainless Steel

300 series investment cast stainless steel is widely used in various industries due to its superior properties. Some of the common applications include:

1. Architectural and Construction: 300 series stainless steel is used in architectural facades, handrails, and other decorative elements due to its corrosion resistance and aesthetically pleasing appearance.

2. Automotive Industry: The high strength and corrosion resistance of 300 series stainless steel make it suitable for automotive components, such as exhaust systems and exhaust manifolds.

3. Chemical Industry: The excellent corrosion resistance of 300 series stainless steel makes it ideal for equipment and containers used in the chemical industry, such as reactors, pipes, and valves.

4. Food and Beverage Industry: 300 series stainless steel is widely used in food processing and storage equipment due to its high hygiene standards and corrosion resistance.

5. Aerospace Industry: The high strength and resistance to heat and corrosion of 300 series stainless steel make it suitable for aerospace components, such as turbine blades and engine parts.

Advantages of Using 300 Series Investment Cast Stainless Steel

Using 300 series investment cast stainless steel offers several advantages:

1. Longevity: The excellent corrosion resistance and high strength of 300 series stainless steel ensure that components and structures have a long service life.

2. Cost-Effective: Although the initial cost of 300 series stainless steel may be higher than some other materials, its long service life and reduced maintenance costs make it a cost-effective choice.

3. Versatility: 300 series stainless steel can be used in various applications and environments, making it a versatile material.

4. Environmental Benefits: The recyclability of stainless steel and its non-toxic properties make it an environmentally friendly choice.

Challenges of Using 300 Series Investment Cast Stainless Steel

Despite its numerous advantages, there are some challenges associated with using 300 series investment cast stainless steel:

1. High Cost: The high cost of 300 series stainless steel can be a barrier for some applications, especially when large quantities are required.

2. Complexity of Design: The design and manufacturing of investment cast parts can be complex, requiring specialized expertise and equipment.

3. Welding: Although 300 series stainless steel has good weldability, improper welding techniques can lead to issues such as stress corrosion cracking.

4. Heat Treatment: Certain grades of 300 series stainless steel require heat treatment to achieve optimal properties, which can add complexity to the manufacturing process.

5. Maintenance: While 300 series stainless steel is corrosion-resistant, it still requires regular maintenance to ensure its longevity, such as cleaning and inspecting for signs of wear or damage.

Common Questions and Answers

1. Question: What is the difference between 300 series investment cast stainless steel and other types of stainless steel?

Answer: 300 series stainless steel is a type of austenitic stainless steel, characterized by its face-centered cubic crystal structure. It is known for its corrosion resistance, high strength, and aesthetically pleasing appearance. Other types of stainless steel, such as ferritic and martensitic, have different properties and applications.

2. Question: Can 300 series investment cast stainless steel be used in high-temperature environments?

Answer: Yes, certain grades of 300 series stainless steel, such as 304 and 316, can be used in high-temperature environments due to their excellent heat resistance.

3. Question: What are the benefits of using investment casting for 300 series stainless steel?

Answer: Investment casting allows for the production of complex shapes with high precision and excellent surface finish. This makes it ideal for applications where the aesthetics and structural integrity are critical.

4. Question: Can 300 series investment cast stainless steel be recycled?

Answer: Yes, stainless steel is 100% recyclable. Recycling stainless steel saves energy and reduces environmental impact.

5. Question: How can I ensure the quality of 300 series investment cast stainless steel parts?

Answer: To ensure the quality of 300 series investment cast stainless steel parts, it is essential to work with a reputable supplier that has experience in investment casting and quality control processes. Regular inspection and testing throughout the manufacturing process can also help identify and address any potential issues.