The Investment Casting Process

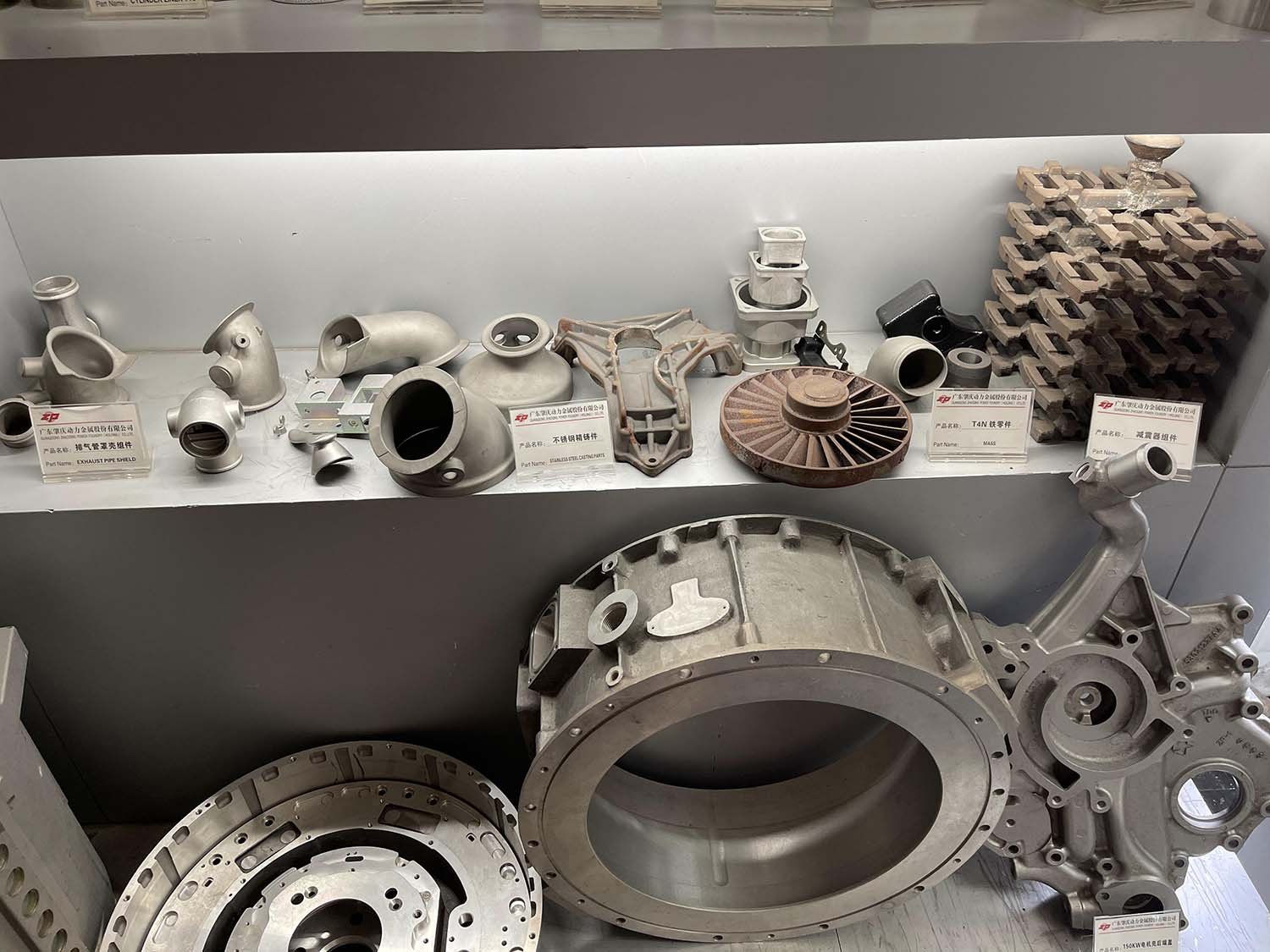

The investment casting process involves creating a wax pattern and layering it with sand and slurry until a strong shell envelopes the model. After melting out the wax, molten steel such as stainless steel or cobalt will be poured into the mold, creating a perfect duplicate of the original wax pattern. Compared to machining a part, investment casting can economically offer undercuts, high definition, complex detail and a smooth surface finish.

Investment casting is most suitable for small parts at large volumes. Most often, investment casting is the only way a part can be economically manufactured with low tooling costs and less material waste. With less waste, it is also better for the environment. If your metal component is small to medium in size and weight, consider investment casting over other processes such as sand casting or die casting.

The investment casting process allows for precision tolerances of 0.005 in/in for parts with complex geometry. For surface finishes, the standard is 120 rms. Our current size capabilities are up to 18 inches and 50 pounds.

If you require prototypes before going into production, we offer rapid prototype services using 3D printing technology and CAD software. These prototypes can be made in just a few days. Professional Manufacturer Custom Sand Casting Part Auto Parts Metal Die Casting Parts Custom Die casting auto parts Stainless steel parts sand casting die casting aluminum parts

Guangdong Bridge Technology Co Ltd. is a solution for projects of any volume and with over 100 alloys to choose from such as stainless steel, aluminum, and cobalt. We have partnered with some of the most essential industries, such as military, medical, food and beverage, oil & gas, and agriculture, to produce the small parts that keep our society alive.

Get in touch with us today to learn howGuangdong Bridge Technology Co Ltd. can help. heyanli

광동 브릿지 테크놀로지 유한회사

광둥성 광저우시 화두구 영빈대로 185호 Jiahua Plaza 3호관 1106호

WhatsApp:0086 134 2210 8513

mail:821460933@qq.com

mail:cindeellahe20@gmail.com

http://www.bridge.wiki